Engineered Wood Floors

Many people are choosing wide plank engineered wood flooring over solid as it is more stable and easier to install. This is true, but not all engineered wood floors are manufactured to the same standard leaving many people confused and disappointed. This has led some people to believe that ‘Engineered Wood Floors are Not Real Wood.’ Many times, I have had clients tell me “I don’t want an engineered wood floor as I want a real wood floor.”

Let us discuss how an engineered wood floor is made and what areas you need to check for to make sure you are getting a high-quality engineered wood floor.

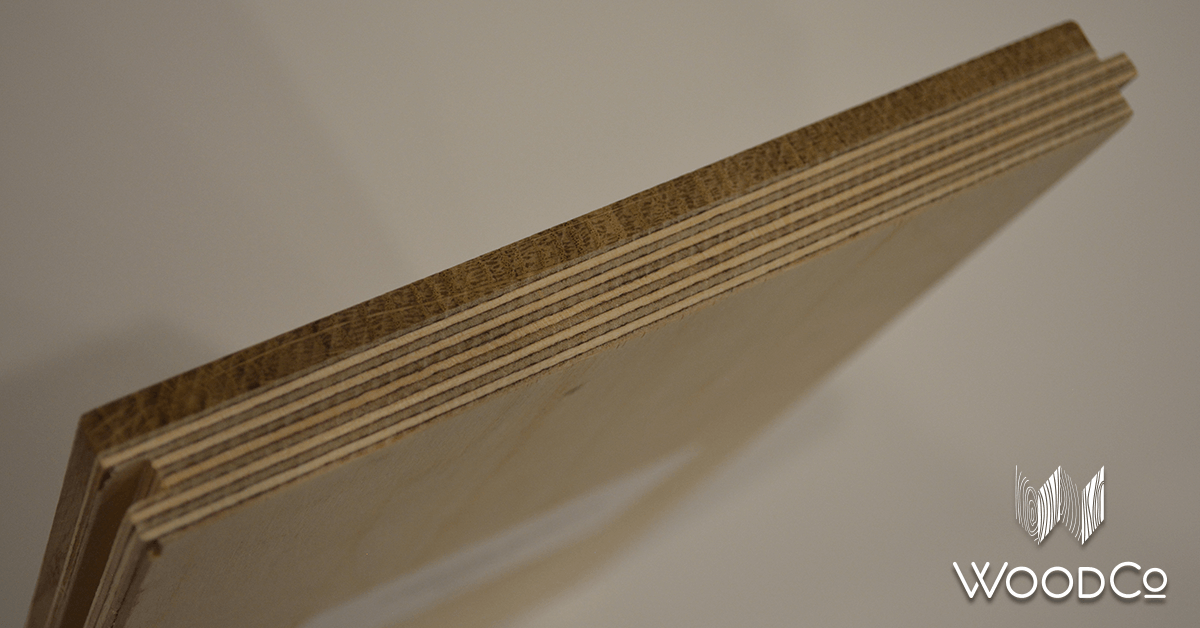

The Construction

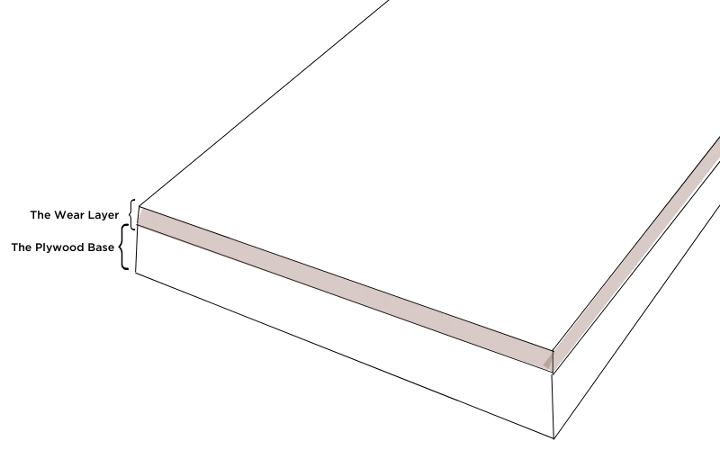

An engineered hardwood floor is made up of two pieces glued together: the lamella (the top layer -- also known as the wear layer), and the plywood base. The lamellas are cut from a piece of lumber and then glued onto a precut piece of plywood. Once the glue has set, the boards are then milled into flooring.

To ensure the product you are considering is a quality engineered wood floor and will last a long time you need to make sure it fits the below standards:

Plywood Base: 9-ply +

Thickness of Wear Layer (Lamella): 4mm (0.157” Just over 1/8”) – 6mm (0.236” almost 1/4”)

Total Thickness of Floor: 5/8” or 3/4”

Let us discuss each of these areas a little deeper so you know the reason behind these numbers.

The Plywood Base

Most engineered wood floors will have some sort of a plywood base, although a few may have a ‘solid core’ which is made from one single piece of wood. The plywood is the key component of stability for an engineered floor. High quality plywood such as Baltic Birch is very stable because it is constructed of many thin layers which go in different directions. The more layers the plywood has the more stable it will be. Also, for an engineered wood floor to be balanced, you need to have an odd number of layers in your plywood base. To ensure your floor will be stable and last a long time make sure you stay away from ‘solid core’ engineered wood floors and any plywood bases that have less than nine layers.

The number one reason that an engineered wood floor fails is because it de-laminates. Many people automatically presume it is the wear layer that de-laminates from the plywood base, but it is usually the plywood itself that comes apart. You want to make sure that the Baltic Birch Plywood base is marine grade or WBP (Weather & Boil Proof). This means that specific glues are used to make the plywood and it is more durable. Many people are not aware of this and thus many manufacturers do not list this information online, so be sure to ask.

Thickness of Wear Layer

There is a happy medium in this area. Too thin and too thick will both potentially create you issues.

When you sand and refinish a wood floor you remove approximately 1mm of wood. To ensure you can sand and refinish your floor at least a couple of times, we recommend that you do not go below the 4mm wear layer thickness.

However thicker is not always better. We recommend that you do not exceed a 6mm wear layer as this can compromise the stability of the floor. Why? Because, a solid piece of wood, such as the wear layer (lamella), is a natural wood product that will expand and contract in response to moisture changes. You then glue this piece of wood onto a very stable base, such as a 11-Ply Baltic Birch Plywood. If moisture changes occur causing the lamella to shrink, because of its thickness it will have considerable strength and may split as the plywood base is more stable (lots of thin layers) and will not shrink at the same rate.

Total Thickness

This is the thickness of the wear layer and plywood base added together. The plywood base should always be thicker than the lamella.

More on the Wear Layer

You now know what the wear layer (lamella) is on an engineered wood floor and how the floor is made. However, there are two separate ways that the lamellas are cut that produce a completely different look.

1) Flat Sliced

2) Rotary Peeled

With a flat sliced lamella, a thick piece of lumber is sliced into several boards around 5mm – 7mm thick. This is then glued onto the plywood base and sanded giving you the 4mm – 6mm wear layer (lamella). This method is the same way solid wood floors are cut and so your engineered floor will have the same look as a solid wood floor.

With the rotary peel method, a knife peels the log creating large sheets of thin wood. The appearance of this wood, especially the grain, will be quite different to the flat sliced wood. This is the least expensive cut of lamella and is commonly used for flooring and panels in North America.

Image from The Hardwood Guys

Plank Size

One of the best parts of an engineered wood floor is each plank will be a lot more stable than a solid wood floor. Allowing you to get much wider planks in engineered wood flooring vs solid wood flooring. However, a lot of engineered wood floors are still around 3” wide and under 6’ long. If you have a large space, you will have a lot of flooring seams in your wood floor. By increasing the size of each plank, you reduce the number of individual pieces giving it a more simplistic and modern look. 5” – 7” wide is great width for standard size rooms. If you have a large space, consider going wider, maybe 8” -12” wide. For a really expansive project, an 18”-20” wide engineered wood floor may give you the minimalistic look you want.

While the flooring width is the most common flooring dimension discussed, flooring lengths are equally important. Long length engineered wood floors go hand in hand with wide planks. The wider you go the longer you need each board to be to prevent your floor looking like brick work. Many manufacturers offer 1’-8’ or the more common in higher end flooring is the 2’-10’ average lengths. Even when companies say the floor will be 2’-10’ lengths, you often get shorter pieces, and the longest plank is usually several feet off the 10’ mark. Make sure you ask what the lengths will be and whether you can expect some 10’ boards in your 2’-10’ floor. If you are considering a wide plank engineered floor that is wider than around 8”, you may want to increase the lengths. Some people will go to a 4’ and longer or a 2’ to 12’ length mix. For the really wide planks, like 18” plus, you will want to increase it a lot more, maybe to 6’ or 8’ minimum lengths.

Health & Environmental

A lot of people are concerned about how their new floor will affect the air quality of your space and you should be. The type of glue used in the production of the engineered wood floor as well as the finish on top of the wood floor are common subjects for concern. VOC’s and formaldehyde have been brought to the attention of many end users after the lawsuit with Lumber Liquidators in 2019. VOC’s stands for Volatile Organic Compounds and are emitted as gases from certain solids or liquids, one of these is formaldehyde. Formaldehyde is a naturally occurring organic compound and is found in every living system including the human body! Hence, formaldehyde free natural products do not exist. Instead make sure you check that the product has ‘no added formaldehyde.’

CARB2 or CARB II compliant is a national standard in the United States for formaldehyde emissions. This regulation meets the highest standards for air quality and contaminants, including California, which have some of the strictest air quality standards in the USA.

A lot of wood flooring in North America today is sadly no longer produced here. Make sure you ask where your wood floor is made and check that it is manufactured in accordance with the high standards we uphold in the United States.

Contact

Questions? Contact our team below for answers to all your wood and flooring needs.